What Happens to Our Recycling?

A group of staff and students toured Bywaters Materials Recovery Facility to find out what happens after you put something in a recycling bin in Tower Hamlets.

We spoke to Bywaters’ brilliant team about how the recycling is sorted and what is taken out before the things we throw away can be turned into something new.

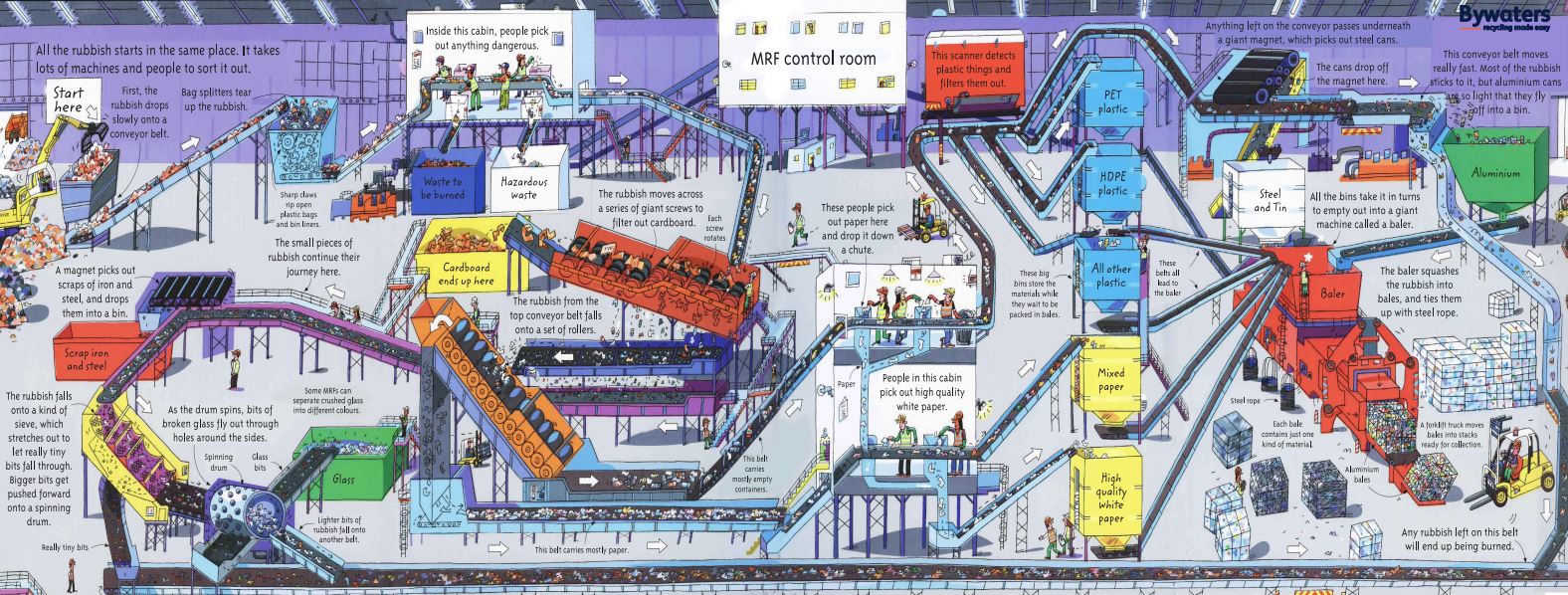

The first thing we saw was trucks filled with mixed recycling being weighed via metal plates at the entrance, before dumping them into a huge mountain in a large empty space. There were only three or so truckloads currently there, with mountains as tall as rooms, and we were told that this was a quite period before the rest of the trucks came in. This much rubbish was generated in just a couple of hours from Bywaters’ customers, the boroughs of Tower Hamlets and Wandsworth.

Cranes picked it up bit by bit and deposited it into the bag splitter, where bin bag and recycling were separated. The recycling is by conveyor belt taken to Waste Operatives who go through the recycling by hand to pick out contaminants - things that shouldn't be in the recycling. While they rescued some things that could be recycled at other facilities, particularly e-waste (batteries, phones, wires...) that should have been disposed of in electrical recycling bins, the rest is general waste which is sent down the river in a boat to another facility where it will be burned for energy.

Cardboard is separated by rotating screws and moving to their own section, while the heavier materials fall through the screws onto a set of rollers that small heavy materials fall through.

From the conveyor belt with small materials, a magnet picks out scraps of metal and a spinning drum picks out glass bits. The remainder of things on this belt will be added to the general waste as they are too small to be recycled, such as shredded paper.

From the conveyor belt, it is further separated by rollers into lighter items such as paper and heavier items like plastic and metal. From the lighter items, Waste Operatives separate high quality white paper and mixed paper. From the heavier items, more Waste Operatives send any paper to the other team. That leaves the conveyor belt with just plastic and metal to sort.

A large machine detects types of plastics and sorts PET, HDPE, and all other plastic to be packed in their own bales. The steel cans are picked out by another magnet, while the aluminium is taken out by a fast-moving conveyor belt. Anything left is added to the general waste.

It was amazing to see the huge scale of all the processes and machines, as well as how many people it takes to sort through everything.

To find more information about Bywaters, you can check out their website. They also have a guide on what can be recycled.

Bywaters MRF Diagram Link [PDF 1,553KB]