We have invested heavily in modern laboratory equipment the past five years allowing us to accurately characterise a wide range of sensor materials.

We have invested heavily in modern laboratory equipment the past five years allowing us to accurately characterise a wide range of sensor materials. In-house radioactive sources (neutron, alpha, gamma, beta) provide for radiation detection assessment and our strong links with international irradiation facilities allow for radiation damage testing.

Cleanroom facility

Our climatically controlled ISO7, class 10,000, clean room is fully equipped with semiconductor test equipment, including:

- a semi-automatic probe station

- an automatic wire bonder and bond puller

- non-contact metrology systems for quality control.

This allows us to validate the quality of semiconductor sensors either fabricated in-house or procured from an external vendor, to assemble and wire bond out sensors to electrical circuits.

Our climatically controlled ISO7 certified clean room is fully equipped with semiconductor test equipment including a semi-automatic probe station, an automatic wire bonder and bond puller, with non-contact metrology systems for quality control.

Semi-conductor characterisation

We have invested heavily in this area over the past five years, including specialist equipment to perform high quality measurements and detector characterisation studies.

Parameter analyser set-up for measuring electrical characteristics of transistors, diodes, capacitors and resistors.

Wire bonding

Modern wire-bonding machines allow us to make fine wire electrical interconnects between our sensors and readout electronics.

-859x627.jpg)

Automatic high speed Hesse BJ820 fine wire wedge bonder for bonding up to 6 wires per second.

Metrology and visual inspection

The SmartScope Flash CNC 200 system is used for both metrology and visual inspection. We also developed a custom built visual capture system for quality control of silicon sensors.

.png)

The OGP SmartScope Flash CNC 200 is equipped with an optical system to determine the z-height of a surface in a contactless manner.

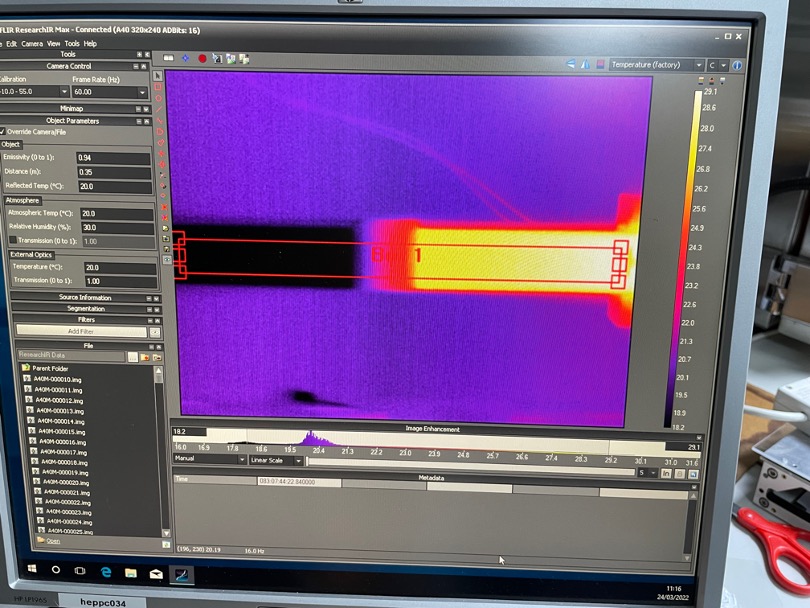

Thermal Impedance Measurement

Bespoke system designed in-house for measuring thermal impedance over a wide range of materials. This is used to help thermal system design and heat flow management.

Temperature profile from infra-red image data

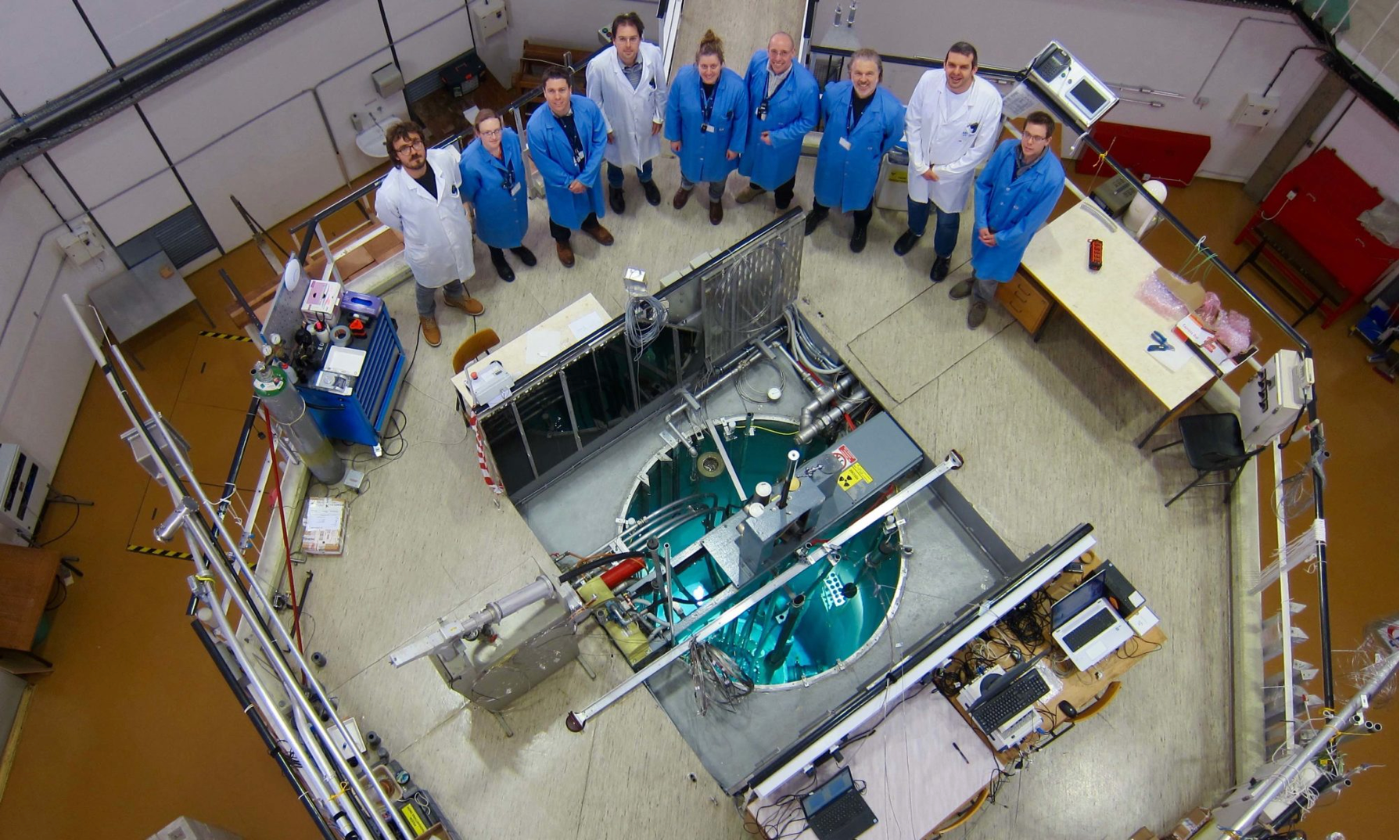

Irradiation testing

In the R&D of technologies for application in radiation environments, testing at irradiation facilities is crucial. We use irradiation facilities both in the UK and internationally to test and verify devices for their application in LHC radiation environments. We also offer consultancy services to companies wishing to explore the radiation resilience of their products. Facilities we use include:

- high dose cobalt-60 gammas

- high flux nuclear reactor neutrons and gammas for material bulk damage studies

- high energy neutrons for atmospheric

Dr Dawson with colleagues from industry atop a TRIGA nuclear research reactor. An Innovate UK funded project for studying radiation damage to ultrasound sensors.

-525x350.jpg)